Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Please enter the email address you’d like your password reset information sent to.

Email format error

Email cannot be empty

Email does not exist

Reset account password

For the account

6-20 characters(letters plus numbers only)

The password is inconsistent

Reset success

Your password was reset. You can log in using your new password.

Login

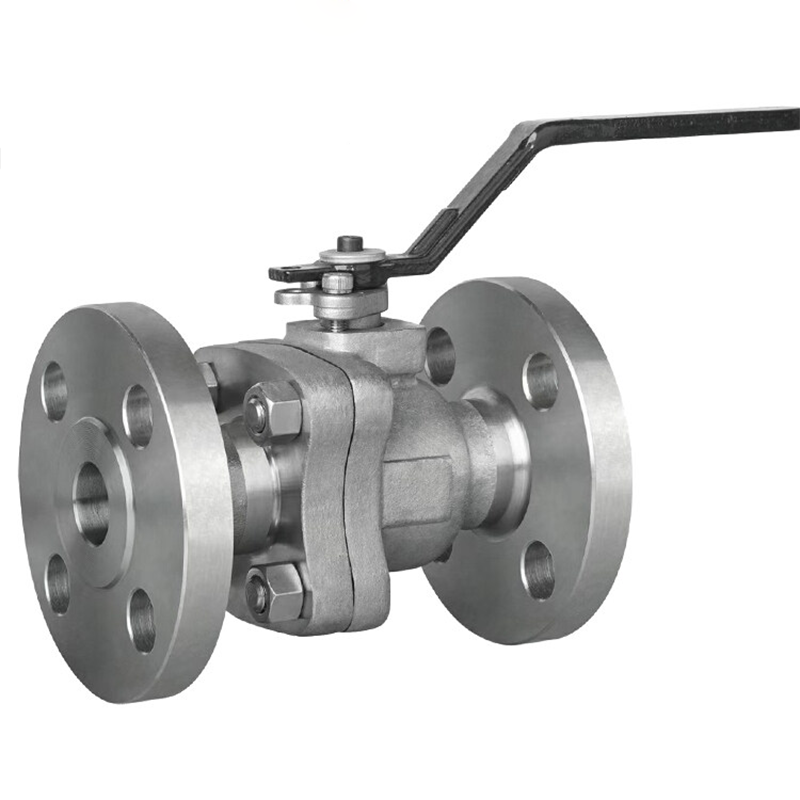

FORGED STEEL BALL VALVE

FORGED STEEL BALL VALVE

Our forged steel ball valve is applicable to various functions and operations, and is suitable for medium to high viscosity pressure. If the pressure exceeds 250ps, I can reach medium and high pressure in the full open position. Dual operation enables the operator to operate easily and comfortably.

Contact us

Inquiry Basket

OEM:

Available

Sample:

Available

Payment:

Other

Place of Origin:

China

Supply Ability:

1000 unit per Month

Contact us

PRODUCT TAGS